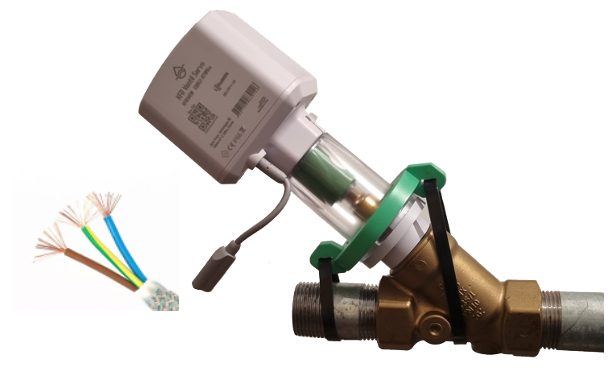

The motor drive designed for angle seat valves, specifically KFR valves, offers a solution for seamlessly retrofitting existing shut-off valves into remotely controlled intelligent devices. This process is achieved without the need to interrupt water supply or cut into the water pipe. The 12V-powered motor is not only water-resistant but also resistant to dirt, ensuring durability up to the power supply. Versatility is achieved through various adapter rings and a sophisticated connection system, allowing the motor to be compatible with modern angle seat valves featuring raising or non-raising stems, ranging from DN15 to DN32.

Incorporating an additional water sensor directly connected to the device enhances functionality, enabling the motor to serve as a leak protection system without the need for further configuration or wireless connectivity. The servo motor's waterproof design makes it suitable for deployment in damp, dirty, and outdoor environments. In its open state, the motor autonomously conducts valve training weekly, involving a closing/opening action by 1/8 turn to remove dirt and scale.

The device is controlled either through the local button or via a dry wire switch input of the existing smart home system (Shelly, Z-Wave, Smartthings, Bosch, Homematic, ...) or your alarm system.

|

|

|

|

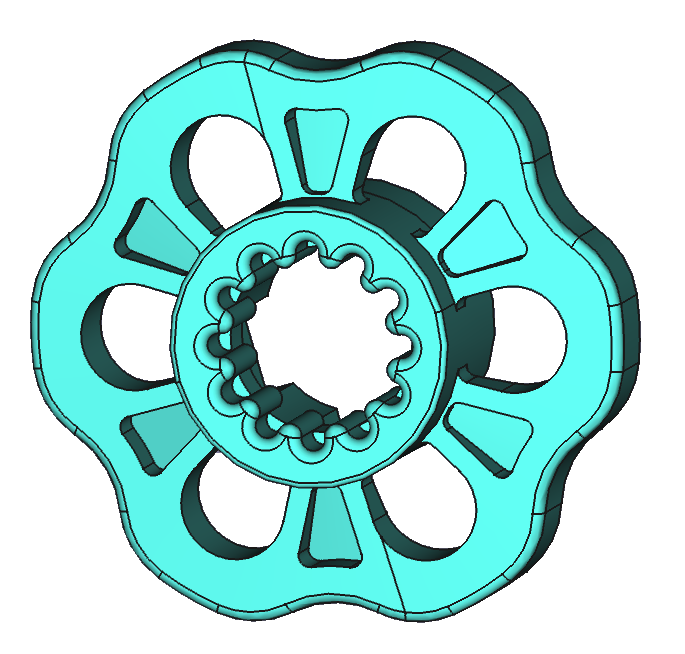

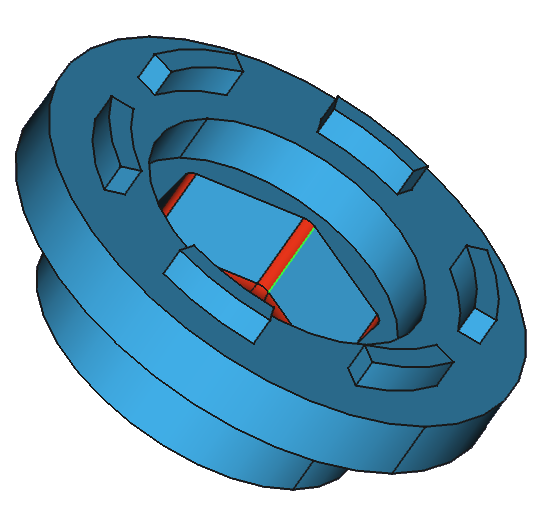

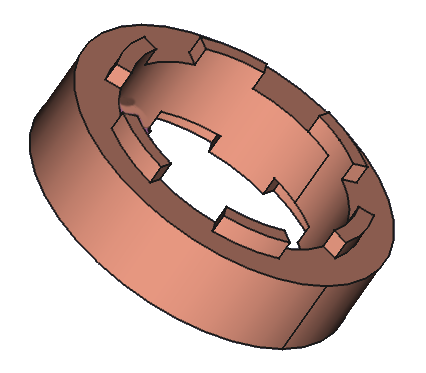

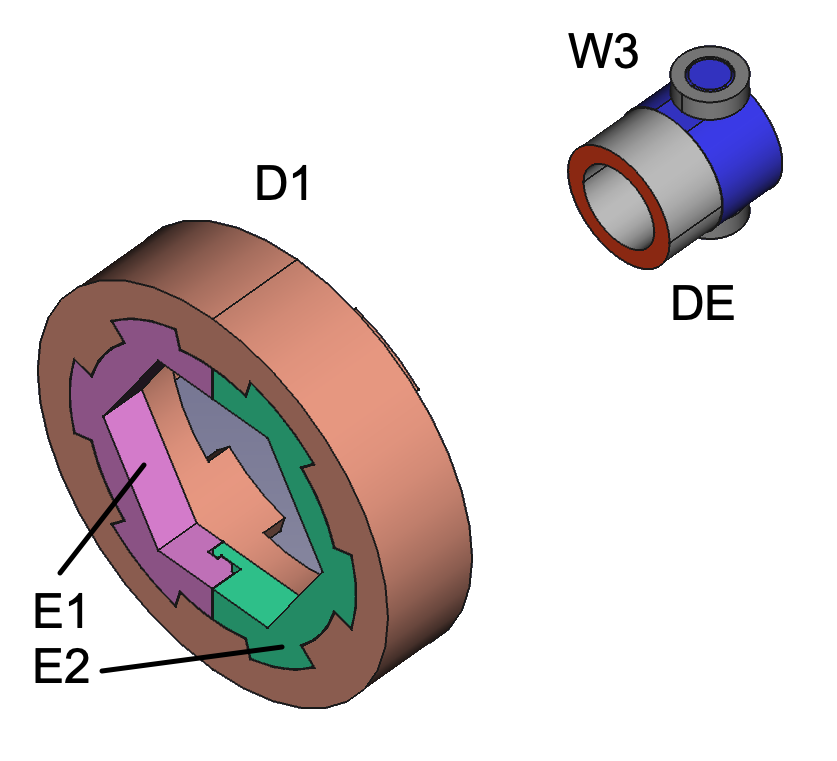

| Handwheel (H) | Inner Coupling (K) | Adapter (Ax) | Distance Rings (D1,D2) |

|

|

|

|

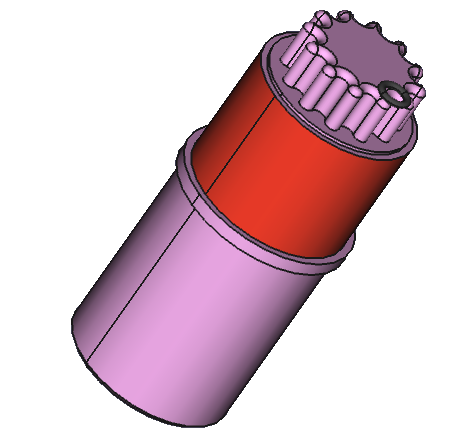

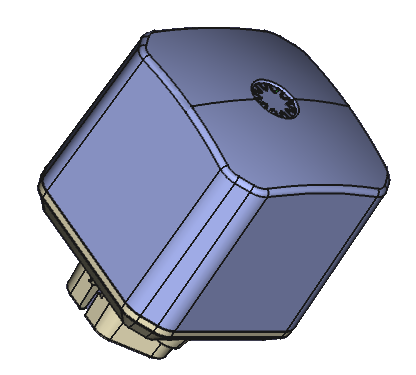

| Ball Bearing Seat (Ws) | Motor (M) | Main Body (G) | Bracket (N) |

The motor drive can be used with all commercially available angle seat valves. However, due to the variety of mechanisms, certain adjustments must be made. When installing, the valve should be normally open (installers recommend opening the valve fully and then closing it slightly with approx. 2 clockwise turns).

The valves from this company have a unique design. You must insert the split ring (E1+E2) into the 24 mm spacer ring (D1) instead of using one of the adapters A1 ... A4. A small additional spacer ring (DE) is placed directly under the ball bearing seat to fix the valve's grease chamber.

If no suitable adapter is available for the valve seat, a custom one must be made. To do this, select an adapter that fits over the valve seat and fill the gap with a two-component resin. This resin is included with the motor. Cut off a piece of the compound with a utility knife and knead it until a uniform color is achieved. Then fill the gaps between the adapter ring and the valve base. After the resin has hardened, the now custom-fit adapter ring can be used.

Note: The resin will adhere firmly to the valve. If this is not desired, lightly oil the valve beforehand. Then the hardened adapter ring can be removed more easily.

Similarly, a ball bearing seat can be adapted for a valve shaft with a square smaller than 6x6 mm. Ensure that the spindle is precisely centered in the ball bearing seat.

Once the motor is mounted and powered, it must determine the correct end positions for the ‘OPEN’ and ‘CLOSE’ positions:

Once the end positions are recognized, the motor will no longer forcefully drive against the valve's endpoints, but will instead count the required motor turns and approach the endpoints gently.

Should you encounter any problem, please give us the opportunity to address it before returning this product. Please check our website www.aqua-scope.com and particularly the support section for answers and help. You can also send a message to info@aqua-scope.com.

While the information in this manual has been compiled with great care, it may not be deemed an assurance of product characteristics. Aqua-Scope shall be liable only to the degree specified in the terms of sale and delivery. The reproduction and distribution of the documentation and software supplied with this product and the use of its contents is subject to written authorization from Aqua-Scope. We reserve the right to make any alterations that arise as the result of technical development.

Aqua-Scope Technology OÜ, Sakala 7-2, 10141 Tallinn, Republic of Estonia, declares that

this radio emitting device works on the following frequences:

Aqua-Scope Technology OÜ, Sakala 7-2, 10141 Tallinn, Republic of Estonia, declares that

this radio emitting device works on the following frequences:

Български С настоящото Aqua-Scope Technology OÜ декларира, че този тип радиосъоръжение KFRDRY01 е в съответств ие с Директива 2014/53/ЕС. Цялостният текст на ЕС декларацията за съответствие може да се намери н а следния интернет адрес: www.aqua-scope.com/ce.

Čeština Tímto Aqua-Scope Technology OÜ prohlašuje, že typ rádiového zařízení KFRDRY01 je v souladu se směrnicí 2014/53/EU. Úplné znění EU prohlášení o shodě je k dispozici na této internetové adrese: www.aqua-scope.com/ce.

Dansk Hermed erklærer Aqua-Scope Technology OÜ, at radioudstyrstypen KFRDRY01 er i overensstemmelse med direktiv 2014/53/EU. EUoverensstemmelseserklæringens fulde tekst kan findes p følgende internetadresse: www.aqua-scope.com/ce.

Deutsch Hiermit erklärt Aqua-Scope Technology OÜ, dass der Funkanlagentyp KFRDRY01 der Richtlinie 2014/53/EU entspricht. Der vollständige Text der EU-Konformitätserklärung ist unter der folgenden Internetadresse verfügbar: www.aqua-scope.com/ce.

Eesti Käesolevaga deklareerib Aqua-Scope Technology OÜ, et kesolev raadioseadme tp KFRDRY01 vastab direktiivi 2014/53/EL nuetele. ELi vastavusdeklaratsiooni tielik tekst on kttesaadav jrgmisel internetiaadressil: www.aqua-scope.com/ce

English Hereby, Aqua-Scope Technology OÜ declares that the radio equipment type KFRDRY01 is in compliance with Directive 2014/53/EU. The full text of the EU declaration of conformity is available at the following internet address: www.aqua-scope.com/ce

Español Por la presente, Aqua-Scope Technology OÜ declara que el tipo de equipo radioeléctrico KFRDRY01 es conforme con la Directiva 2014/53/UE. El texto completo de la declaracin UE de conformidad está disponible en la direccin Internet siguiente: www.aqua-scope.com/ce

Ελληνικά Με την παρούσα ο/η Aqua-Scope Technology OÜ, δηλώνει ότι ο ραδιοεξοπλισμός KFRDRY01 πληροί την οδηγία 2014/53/ΕΕ. Το πλήρες κείμενο της δήλωσης συμμόρ φωσης ΕΕ διατίθεται στην ακόλουθη ιστοσελίδα στο διαδίκτυο: www.aqua-scope.com/ce

Français Le soussigné, Aqua-Scope Technology OÜ, déclare que l'équipement radioélectrique du type KFRDRY01 est conforme la directive 2014/53/UE. Le texte complet de la déclaration UE de conformité est disponible l'adresse internet suivante: www.aqua-scope.com/ce

Hrvatski Aqua-Scope Technology OÜ ovime izjavljuje da je radijska oprema tipa KFRDRY01 u skladu s Direktivom 2014/53/EU. Cjeloviti tekst EU izjave o sukladnosti dostupan je na sljedećoj internetskoj adresi: www.aqua-scope.com/ce

Italiano Il fabbricante, Aqua-Scope Technology OÜ, dichiara che il tipo di apparecchiatura radio KFRDRY01 conforme alla direttiva 2014/53/UE. Il testo completo della dichiarazione di conformit UE disponibile al seguente indirizzo Internet: www.aqua-scope.com/ce

Latviešu Ar šo Aqua-Scope Technology OÜ deklarē, ka radioiekārta KFRDRY01 atbilst Direktīvai 2014/53/ES. Pilns ES atbilstības deklarācijas teksts ir pieejams šādā interneta v ietnē: www.aqua-scope.com/ce Lietuvių Aš, Aqua-Scope Technology OÜ, patvirtinu, kad radijo įrenginių tipas KFRDRY01 atitinka Direktyvą 2014/53/ES. Visas ES atitikties deklaracijos tekstas prieinamas šiuo internet adresu: www.aqua-scope.com/ce

Magyar Aqua-Scope Technology OÜ igazolja, hogy a KFRDRY01 típus rádiberendezés megfelel a 2014/53/EU irányelvnek. Az EUmegfelelőségi nyilatkozat teljes szövege elérhető a következő internetes címen: www.aqua-scope.com/ce

Malti B'dan, Aqua-Scope Technology OÜ, niddikjara li dan it-tip ta' tagħmir tar-radju KFRDRY01 huwa konformi madDirettiva 2014/53/UE. It-test kollu tad-dikjarazzjoni ta' konformit tal-UE huwa disponibbli f'dan l-indirizz talInternet li ġej: www.aqua-scope.com/ce

Nederlands Hierbij verklaar ik, Aqua-Scope Technology OÜ, dat het type radioapparatuur KFRDRY01 conform is met Richtlijn 2014/53/EU. De volledige tekst van de EUconformiteitsverklaring kan worden geraadpleegd op het volgende internetadres: www.aqua-scope.com/ce

Polski Aqua-Scope Technology OÜ niniejszym oświadcza, że typ urządzenia radiowego KFRDRY01 jest zgodny z dyrektywą 2014/53/UE. Pełny tekst deklaracji zgodnośc I UE jest dostępny pod następującym adre sem internetowym: www.aqua-scope.com/ce

Português O(a) abaixo assinado(a) Aqua-Scope Technology OÜ declara que o presente tipo de equipamento de rádio KFRDRY01 está em conformidade com a Diretiva 2014/53/UE. O texto integral da declarao de conformidade está disponível no seguinte endereo de Internet: www.aqua-scope.com/ce

Română Prin prezenta Aqua-Scope Technology OÜ declară că tipul de echipamente KFRDRY01 este în conformitate cu Directiva 2014/53/UE. Textul integral al declarației UE de conformitate este disponibil la următoarea adresă internet: www.aqua-scope.com/ce

Slovensko Aqua-Scope Technology OÜ potrjuje, da je tip radijske opreme KFRDRY01 skladen z irektivo 2014/53/EU. Celotno besedilo izjave EU o skladnosti je na voljo na naslednjem spletnem naslovu: www.aqua-scope.com/ce

Slovensky Aqua-Scope Technology OÜ týmto vyhlasuje, že rádiové zariadenie typu KFRDRY01 je v slade so smernicou 2014/53/EÚ. Úplné EÚ vyhlásenie o zhode je k dispozícii na tejto internetovej adrese: www.aqua-scope.com/ce

Soumi Aqua-Scope Technology OÜ vakuuttaa, että radiolaitetyyppi KFRDRY01 on direktiivin 2014/53/EU mukainen. EUvaatimustenmukaisuusvakuutuksen täysimittainen teksti on saatavilla seuraavassa internetosoitteessa: www.aqua-scope.com/ce

Svenska Härmed försäkrar Aqua-Scope Technology OÜ att denna typ av radioutrustning KFRDRY01 verensstmmer med direktiv 2014/53/EU. Den fullständiga texten till EUförsäkran om verensstämmelse finns på följande webbadress: www.aqua-scope.com/ce

Do not dispose of electrical appliances as unsorted municipal waste, use separate collection

facilities. Contact your local government for information regarding the collection systems

available. If electrical appliances are disposed of in landfills or dumps, hazardous

substances can leak into the groundwater and get into the food chain, damaging health and well-being.

Do not dispose of electrical appliances as unsorted municipal waste, use separate collection

facilities. Contact your local government for information regarding the collection systems

available. If electrical appliances are disposed of in landfills or dumps, hazardous

substances can leak into the groundwater and get into the food chain, damaging health and well-being.